Menene Magnet?

Maganar maganadisu wani abu ne wanda ke yin aiki da karfi akansa ba tare da saduwa ta jiki da wasu kayan ba. Ana kiran wannan ƙarfi magnetism. Ƙarfin maganadisu na iya jan hankali ko tunkuɗewa. Yawancin abubuwan da aka sani sun ƙunshi wasu ƙarfin maganadisu, amma ƙarfin maganadisu a cikin waɗannan kayan ƙanƙane ne. Ga wasu kayan, ƙarfin maganadisu yana da girma sosai, don haka waɗannan kayan ana kiran su maganadisu. Ita kanta kasa ma babbar magana ce.

Akwai maki biyu akan duk maganadiso inda ƙarfin maganadisu ya fi girma. An san su da sanduna. A kan maganadisu na mashaya rectangular, sandunan suna fadin juna kai tsaye. Ana kiran su Pole North ko arewa-neking, da kuma Kudu Pole ko kudu-neman.

Ana iya yin maganadisu kawai ta hanyar ɗaukar magnet ɗin da ke akwai kuma a shafa ɗan ƙaramin ƙarfe da shi. Wannan karfen da ake amfani da shi dole ne a ci gaba da goge shi ta hanya daya. Wannan ya sa electrons a waccan guntun karfe su fara juyi ta hanya guda. Har ila yau wutar lantarki yana da ikon ƙirƙirar maganadisu. Tunda wutar lantarki yawo ne na electrons, lokacin da wayoyin hannu suka motsa a cikin waya suna dauke da irin tasirin da electrons ke jujjuyawa a kusa da tsakiyan atomic. Wannan shi ake kira electromagnet.

Saboda yadda ake tsara electrons ɗin su, ƙarfen nickel, cobalt, iron, da ƙarfe suna yin maganadisu mai kyau sosai. Wadannan karafa na iya zama maganadisu har abada da zarar sun zama maganadiso. Ta haka ɗauke da sunan wuya maganadisu. Duk da haka waɗannan karafa da sauran suna iya zama kamar maganadisu na ɗan lokaci idan an fallasa su ko kuma sun zo kusa da maganadisu mai wuya. Sa'an nan kuma suna dauke da sunan soft magnets.

Yadda Magnetism ke Aiki

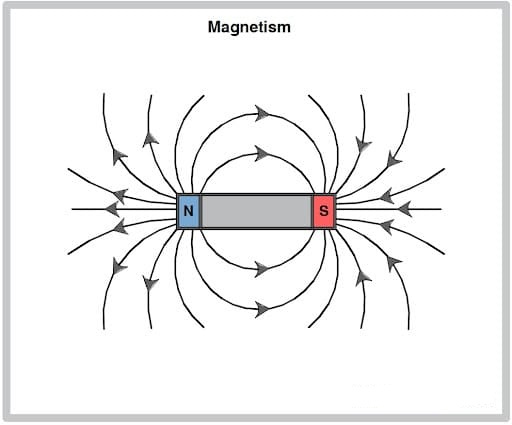

Magnetism yana faruwa lokacin da ƙananan ƙwayoyin da ake kira electrons suna motsawa ta wata hanya. Dukkan kwayoyin halitta sun kunshi raka’o’in da ake kira atoms, wadanda su kuma sun hada da electrons da sauran barbashi, wadanda su ne neutrons da protons. Wadannan electrons sukan yi ta jujjuyawa a cikin tsakiya, wanda ya ƙunshi sauran barbashi da aka ambata a sama. Karamin karfin maganadisu yana faruwa ne sakamakon jujjuyawar wadannan electrons. A wasu lokuta, yawancin electrons a cikin abin suna juyawa ta hanya ɗaya. Sakamakon duk waɗannan ƙananan ƙarfin maganadisu daga electrons shine babban maganadisu.

Ana Shirya Foda

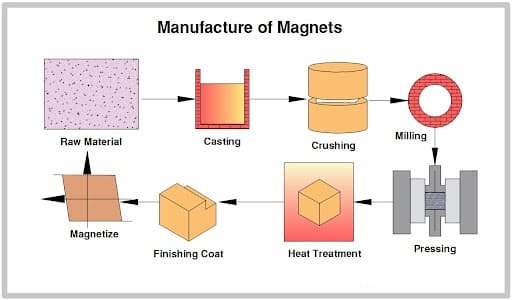

Madaidaicin adadin ƙarfe, boron, da neodymium ana dumama su don narkewa a ƙarƙashin injin injin ko a cikin tanderun narkewa ta hanyar amfani da iskar gas. Amfani da injin shine don hana halayen sinadarai tsakanin kayan narkewa da iska. Lokacin da narkakken gawa ya yi sanyi, sai a karye shi a niƙasa shi ya zama ƙananan ɗigon ƙarfe. Bayan haka, ana niƙa ƙananan ɓangarorin kuma a niƙa su cikin foda mai kyau wanda ke tsakanin 3 zuwa 7 microns a diamita. Sabuwar foda da aka kafa tana da ƙarfi sosai kuma tana iya haifar da ƙonewa a cikin iska kuma dole ne a kiyaye shi daga kamuwa da iskar oxygen.

Isostatic Compaction

Tsarin isostatic compaction kuma ana kiransa latsawa. Ana ɗaukar karfen foda kuma a sanya shi a cikin wani tsari. Ana kuma kiran wannan nau'in mutuwa. Domin kayan foda ya kasance cikin layi tare da abubuwan foda ana yin ƙarfin maganadisu, kuma a cikin lokacin da ake amfani da ƙarfin maganadisu, ana amfani da raguna na hydraulic don matsawa gaba ɗaya zuwa cikin inci 0.125 (0.32 cm) na shirin da aka tsara. kauri. Ana amfani da matsa lamba yawanci daga 10,000 psi zuwa 15,000 psi (70 MPa zuwa 100 MPa). Ana kera sauran kayayyaki da sifofi ta hanyar sanya abubuwan a cikin akwati da aka kwashe kafin a danna su cikin siffar da ake so ta hanyar iskar gas.

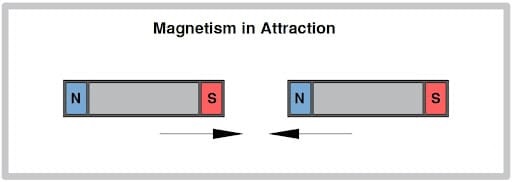

Yawancin kayan da ake ɗaukar misali, itace, ruwa, da iska suna da halayen maganadisu waɗanda suke da rauni sosai. Magnets suna jan hankalin abubuwan da suka ƙunshi tsoffin karafa da ƙarfi sosai. Har ila yau, suna jan hankali ko tunkuɗe wasu maɗaukaki masu ƙarfi idan an kusantar da su. Wannan sakamakon saboda kowane maganadisu yana da sanduna biyu masu gaba da juna. Sandunan kudu suna jan hankalin sandunan arewa na sauran magneto, amma suna korar sauran sandunan kudu kuma akasin haka.

Manufacturing Magnets

Hanyar da aka fi amfani da ita wajen kera maganadisu ita ce ake kira foda metallurgy. Tunda maganadisu ya ƙunshi abubuwa daban-daban, hanyoyin kera su ma sun bambanta da nasu na musamman. Misali, electromagnets ana yin su ne ta hanyar amfani da dabarun simintin ƙarfe, yayin da ake kera maɗaukaki masu sassauƙa na dindindin a cikin matakai da suka haɗa da extrusion na filastik inda ake gauraya albarkatun ƙasa a cikin zafi kafin a tilasta su ta hanyar buɗewa ƙarƙashin matsanancin yanayi. Da ke ƙasa akwai tsarin masana'anta na maganadisu.

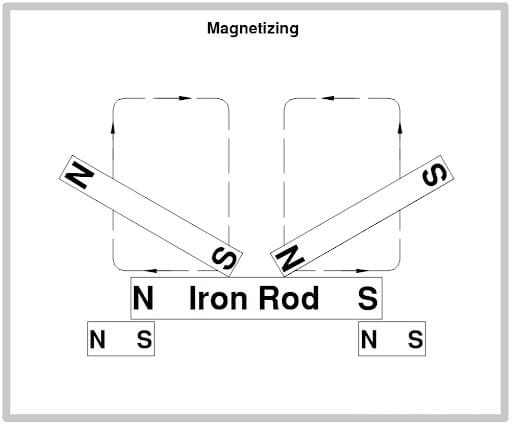

Duk mahimman abubuwan da ke da mahimmanci na zaɓin maganadisu yakamata a kawo su ƙarƙashin tattaunawa tare da ƙungiyoyin injiniya da samarwa. Tsarin maganadisu akan hanyoyin masana'anta na maganadisu, har zuwa wannan lokaci, kayan abu ne na ƙarfe da aka matsa. Ko da yake an yi amfani da shi a kan ƙarfin maganadisu yayin aiwatar da matsi na isostatic, ƙarfin bai kawo tasirin maganadisu ga kayan ba, kawai ya jera ƙwayoyin foda mara kyau. Ana kawo guntun tsakanin sandunan na'urar lantarki mai ƙarfi daga baya kuma an daidaita shi a cikin alkiblar maganadisu. Bayan an sami kuzarin lantarki, ƙarfin maganadisu yana daidaita wuraren maganadisu a cikin kayan, yana mai da yanki ya zama maganadisu mai ƙarfi na dindindin.

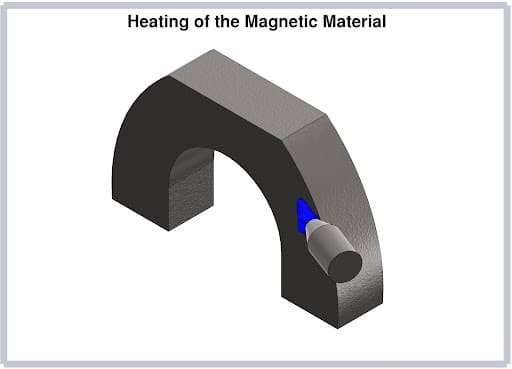

Dumama na Material

Bayan aiwatar da ƙaddamarwar isostatic an raba slug na ƙarfe mai foda daga mutu kuma an saka shi a cikin tanda. Sintering shine tsari ko hanyar ƙara zafi zuwa matsewar ƙarafa da aka matsa don a canza su zuwa gaɗaɗɗen, guntuwar ƙarfe mai ƙarfi daga baya.

Tsarin sintiri ya ƙunshi matakai uku. A lokacin aiwatar da matakin farko, kayan da aka matsa yana zafi a cikin ƙananan yanayin zafi don fitar da duk danshi ko duk abubuwa masu gurɓataccen abu waɗanda wataƙila an kama su yayin aiwatar da haɗin kai. A lokacin sintering mataki na biyu, akwai tashin a zazzabi zuwa kusan 70-90% na gami ta narkewa. Ana ajiye zafin jiki a wurin na tsawon sa'o'i ko kwanaki domin ƙananan ɓangarorin su yi daidai, haɗa su kuma su haɗa su tare. Mataki na ƙarshe na sintering shine lokacin da aka sanyaya kayan a hankali a hankali a cikin haɓakar zafin jiki mai sarrafawa.

Rufe kayan

Bayan tsarin dumama ya zo da tsari na annealing. Wannan shine lokacin da kayan da aka ƙera ke ɗaukar wani mataki-mataki sarrafa dumama da tsarin sanyaya don watsar da kowane ko duk sauran damuwa waɗanda suka rage a cikin kayan kuma suyi ƙarfi.

Ƙarshen Magnet

Abubuwan maganadisu na sama sun ƙunshi wani matakin ko digiri na injina, kama daga niƙa su santsi da layi ɗaya ko ƙirƙirar ƙananan sassa daga toshe maganadiso. Abubuwan da ke yin maganadisu suna da wuyar gaske kuma suna gatsewa (Rockwell C 57 zuwa 61). Don haka wannan abu yana buƙatar ƙafafun lu'u-lu'u don matakan slicing, ana kuma amfani da su don abrasive ƙafafun don tafiyar matakai. Ana iya yin aikin slicing tare da madaidaicin madaidaici kuma yawanci yana kawar da buƙatar aiwatar da niƙa. Matakan da aka ambata a sama suna buƙatar yin su a hankali don a rage guntuwa da tsagewa.

Akwai lokuta inda tsarin maganadisu na ƙarshe ko sifar ya dace sosai don aiki tare da sifar niƙa na lu'u-lu'u kamar burodin burodi. Sakamakon ƙarshe a cikin sifar ƙarshe ana kawo shi bayan dabaran niƙa kuma dabaran niƙa tana ba da ingantattun ma'auni. Samfurin da aka shafe yana kusa da ƙayyadaddun siffar da girman da ake so a yi. Kusa da sifar yanar gizo shine sunan da yawanci ake ba da wannan yanayin. Tsarin mashin ɗin ƙarshe da na ƙarshe yana kawar da duk wani abu da ya wuce gona da iri kuma yana gabatar da ƙasa mai santsi sosai inda ake buƙata. A ƙarshe don rufe farfajiyar an ba da kayan kariya mai kariya.

Tsarin Magnetizing

Magnetizing yana biye da tsarin ƙarewa, kuma lokacin da aka yi aikin masana'anta, magnet ɗin yana buƙatar caji don samar da filin maganadisu na waje. Don yin wannan, ana amfani da solenoid. Solenoid wani babban silinda ne wanda za'a iya sanya girman maganadisu daban-daban da siffofi ko kuma tare da kayan gyara ana yin solenoid don ba da samfuran maganadisu ko ƙira iri-iri don guje wa haɗawa da haɗa waɗannan ƙaƙƙarfan maganadisu a cikin yanayin magnetized manyan majalisai za a iya yin magnetized. . Ya kamata a yi la'akari da buƙatun filin maganadisu, waɗanda suke da mahimmanci.

Lokacin aikawa: Jul-05-2022