Menene Magnetic Coupling?

Magnetic Couplingsabon nau'in haɗin gwiwa ne wanda ke haɗa babban mai motsi da injin aiki ta hanyar ƙarfin maganadisu na maganadisu na dindindin.Haɗin kai na Magnetic baya buƙatar haɗin injin kai tsaye, amma yana amfani da hulɗar tsakanin maɗauran maganadisu na dindindin na duniya, yana amfani da filin maganadisu don kutsawa wani tazara mai nisa da halaye na kayan abu don watsa makamashin inji.

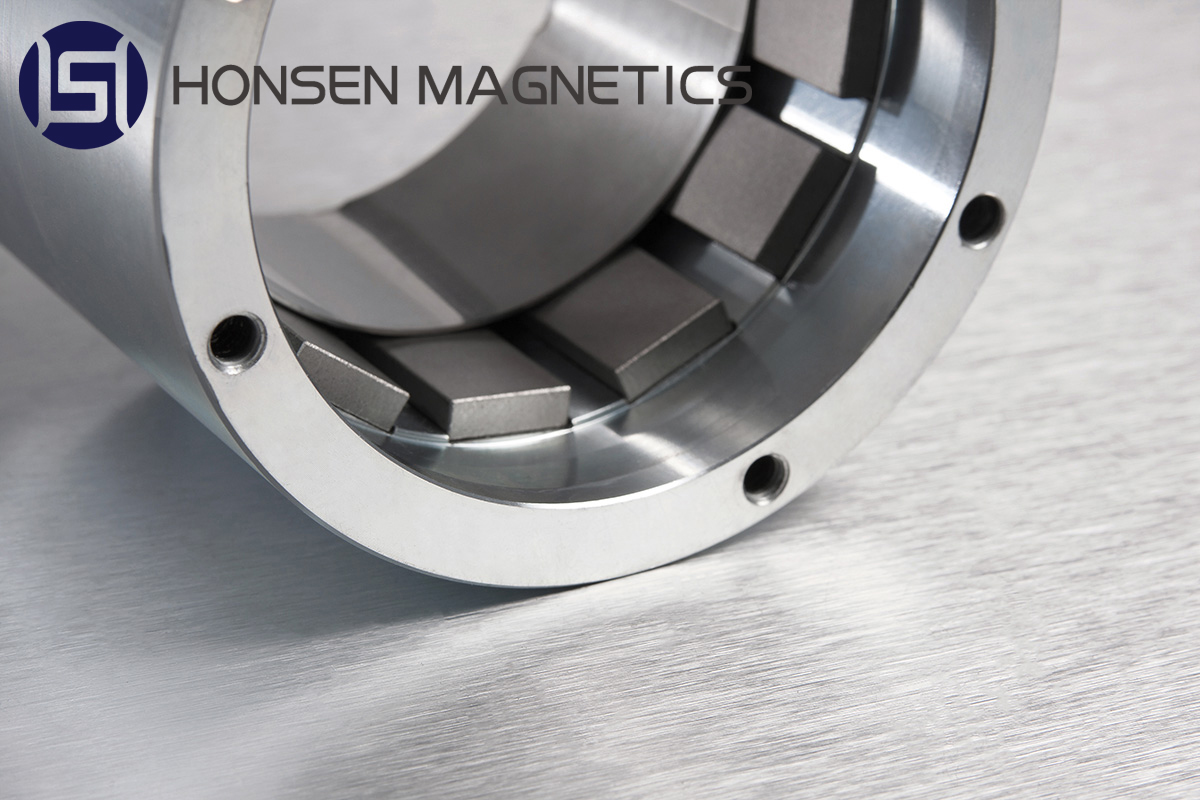

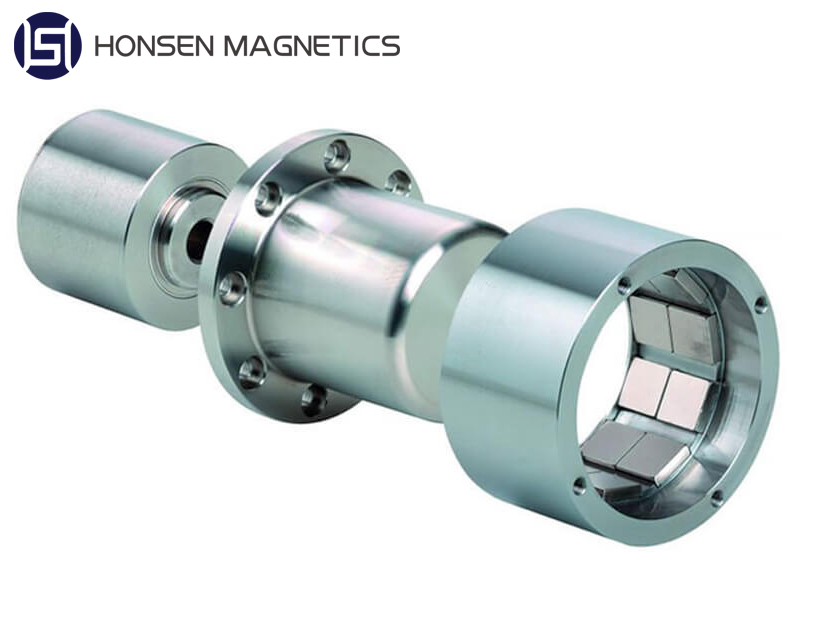

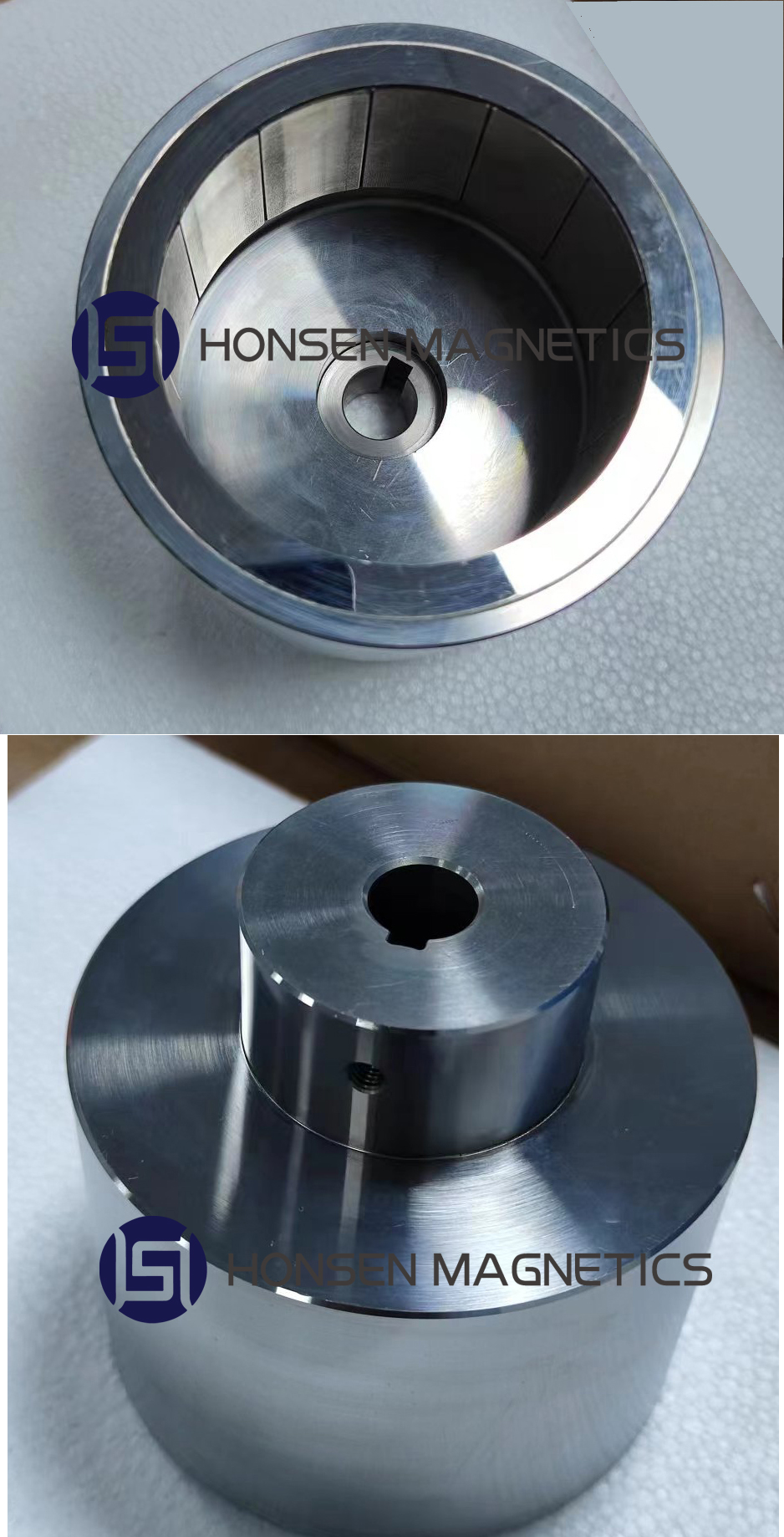

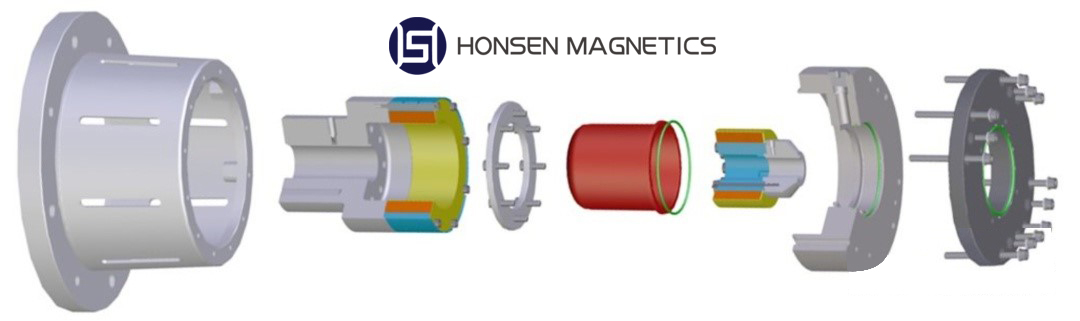

Haɗin gwiwar maganadisu galibi ya ƙunshi na'ura mai jujjuyawar waje, na'ura mai juyi na ciki, da abin rufewa (keɓe hannun riga).Ana raba rotors guda biyu ta hanyar murfin keɓewa a tsakiya, tare da magnetin ciki da aka haɗa da sashin da aka kunna da kuma magnet ɗin waje da aka haɗa da bangaren wutar lantarki.

Za a iya keɓance mahaɗar maganadisu.Maɗaukaki na dindindin gabaɗaya ana amfani da suSmCokoNdFeB maganadisu, kuma ana buƙatar ƙayyadadden ƙima bisa ga zafin aiki, yanayin aiki, da karfin haɗakarwa.An yi harsashi gabaɗaya da bakin karfe (Q235A, 304/316L).

A Magnetic couplings za a iya amfani da daban-daban irin farashinsa da mahautsini kamar dunƙule farashinsa, gear farashinsa, da dai sauransu The Magnetic couplings za a iya amfani da su cimma sealless farashinsa don hana lalacewa lalacewa ta hanyar lalata ruwa kafofin watsa labarai wucewa ta shaft like.Hakanan za'a iya amfani da na'urorin haɗi na Magnetic zuwa na'urorin da za a iya jujjuya wutar lantarki, irin su famfo mai ruwa, da fasahohi iri-iri da na'urorin haƙon mai mai zurfi.

Rarraba Haɗin Magnetic

- An rarraba shi cikin watsawar maganadisu, an raba shi zuwa watsa aiki tare (planar da coaxial), watsawar yanzu, da watsawar hysteresis;

- Rarraba cikin motsi na linzamin kwamfuta, motsi na jujjuyawar, da motsi mai haɗaka dangane da yanayin motsi;

- An rarraba shi zuwa sassa daban-daban, ana iya raba shi zuwa mahaɗaɗɗen haɗin gwal na cylindrical da faifan faifai magnetic couplings;

- An rarraba shi cikin ƙa'idodin aiki daban-daban, ana iya raba shi zuwa haɗin haɗin gwiwar maganadisu na aiki tare da haɗin haɗin magnetic asynchronous.

- An rarraba su cikin shimfidar abubuwan maganadisu na dindindin, an rarraba su cikin nau'in tazara da aka tarwatsa da kuma nau'in turawa da aka haɗa.

Menene manyan sigogin fasaha na Magnetic Coupling?

Lokacin zabar mahaɗaɗɗen maganadisu, ya zama dole a cika la'akari da dalilai kamar takamaiman yanayin aikace-aikacen, injina da halayen kaya, da buƙatun aiki, kuma zaɓi sigogin fasaha masu dacewa da tsarin daidaitawa.

Magnetic coupling shine na'urar watsawa wanda ke amfani da karfin filin maganadisu don watsa karfin wuta, kuma manyan sigoginsa na fasaha sun haɗa da abubuwa masu zuwa:

- Matsakaicin juzu'i: yana wakiltar matsakaicin juzu'in da mahaɗar maganadisu ke iya fitarwa.Wannan siga yana da alaƙa da kusanci da yanayin aikace-aikacen, kuma gabaɗaya, wajibi ne a zaɓi madaidaicin ƙimar juzu'i bisa ainihin buƙatu.

- Gudun aiki: yana wakiltar matsakaicin saurin da haɗin gwiwar maganadisu zai iya jurewa.Wannan siga yana rinjayar kewayon amfani da haɗin gwiwar maganadisu, kuma gabaɗaya, saurin aiki wanda zai iya biyan buƙatu ya kamata a zaɓi.

- Ƙarfin hasara: Yana nufin ikon da aka haɗa ta hanyar haɗin gwiwar maganadisu don canza ƙarfin maganadisu zuwa makamashin thermal ko wasu nau'ikan asara.Karamin ƙarfin hasara, mafi girman ingancin haɗin gwiwar maganadisu, da samfuran da ke da ƙarancin hasara ya kamata a zaɓa gwargwadon yiwuwa.

Menene halayen aikin Magnetic Couplings?

Magnet Coupling wani nau'in haɗakarwa ne dangane da watsa ƙarfin maganadisu ta hanyarm kayan maganadisu, wanda ke da halaye masu zuwa:

- High watsa ingancin aiki: Idan aka kwatanta da na gargajiya couplings, Magnetic couplings amfani da m maganadisu kayan kamar yadda Magnetic kafofin watsa labarai, haifar da mafi girma watsa yadda ya dace, kai sama da 99%.

- Babban karfin juyi: Saboda babban samfurin makamashin maganadisu na kayan maganadisu na dindindin, abubuwan haɗin maganadisu na girman iri ɗaya na iya jure juriya mafi girma idan aka kwatanta da haɗin kai na gargajiya.

- Madaidaicin jujjuyawar juzu'i: Matsakaicin watsawar haɗin gwiwar maganadisu yana da alaƙa da alaƙa da saurin shigarwar, don haka yana iya daidaita karfin juzu'i wanda ya dace da buƙatun a cikin aiki mai amfani kuma yana da ƙarfin daidaitawa.

- Karfin magnetic kwanciyar hankali: Abubuwan maganadisu na dindindin suna da kwanciyar hankali mai ƙarfi da dawo da filin maganadisu.Ko da a cikin yanayin zafi mai zafi da zafi, ba za a sami canje-canje na maganadisu ba, don haka yana da tsawon rayuwar sabis.

- Ƙaddamar da makamashi da kariyar muhalli: Saboda amfani da watsawar maganadisu a cikin mahaɗaɗɗen maganadisu, idan aka kwatanta da na'urorin lantarki na gargajiya, ba sa haifar da rikici na makamashi, asarar zafi, da gurɓataccen hayaniya, don haka suna da kyakkyawan aikin ceton makamashi da kare muhalli.

Me yasa za mu iya yin mafi kyau

Honsen Magneticsƙware a cikin samarwa da masana'anta naMagnetic majalisaida Magnetic couplings.Babban ƙungiyar ta ƙunshi gabaɗayan injiniyoyin ƙirar maganadisu da injiniyoyi masu ƙira.Bayan shekaru na haɗin kai na kasuwa, mun kafa ƙungiyar balagagge: daga ƙira, da samfurin zuwa bayarwa, muna da kayan aiki da kayan aiki da kayan aiki waɗanda za su iya jimre wa yawan samarwa, wasu daga cikinsu an tsara su da kuma kerarre da kanmu, Mun horar da ƙungiya. na ƙwararrun ma'aikatan samarwa.

Ba wai kawai muna samar da SERVICE DAYA-TSAYA na isar da samfurin ƙirar tsari ba amma kuma muna ƙoƙari don daidaito a cikin samfuran tsari.Muna nufin ci gaba da haɓakawa da rage tsangwama na ɗan adam gwargwadon yiwuwa.

Fa'idodinmu a cikin kera Magnet Couplings:

- Sanin nau'ikan maganadisu daban-daban, mai iya ƙididdigewa da haɓaka da'irorin maganadisu.Za mu iya ƙididdige da'irar maganadisu.Misali, lokacin da abokin ciniki ya ƙididdige karfin juzu'i na haɗin gwiwar maganadisu na dindindin, za mu iya samar da mafi kyawu kuma mafi ƙarancin farashi dangane da sakamakon lissafin.

- Kwararrun injiniyoyin injiniyoyi, da inji Properties, girma tolerances, da sauran al'amurran naMagnetic majalisaian tsara su kuma suna duba su.Za su kuma samar da mafi kyawun tsarin sarrafawa bisa albarkatun masana'antar.

- Neman daidaiton samfur.Akwai nau'ikan abubuwan maganadisu iri-iri da hadaddun matakai, kamar tsarin gluing.Manne da hannu na iya bambanta daga mutum zuwa mutum, kuma ba za a iya sarrafa adadin manne ba.Injin rarraba atomatik akan kasuwa ba zai iya daidaitawa da samfuranmu ba.Mun tsara kuma mun samar da tsarin rarrabawa don sarrafawa ta atomatik don kawar da abubuwan ɗan adam.

- ƙwararrun ma'aikata da ci gaba da haɓakawa!Haɗin mahaɗar maganadisu da tarukan maganadisu na buƙatar ƙwararrun ma'aikatan taro.Mun ƙirƙira da ƙera kayan aiki na musamman da kayan aiki da yawa don rage ƙarfin aiki, haɓaka inganci, da ƙara tabbatar da daidaiton samfur.

Kayan aikin mu

Yadda muka cimma shi

Sauraron bukatun abokin ciniki

Domin fahimtar cikakken maƙasudin abokin ciniki, za mu yi la'akari da ba kawai maɓalli na ayyuka na majalissar maganadisu ba har ma da dalilai kamar yanayin aiki, hanyoyin amfani, da yanayin sufuri na samfurin.Ta hanyar samun cikakkiyar fahimtar waɗannan bangarorin, za mu iya shirya yadda ya kamata don lokaci na ƙira na gaba.Wannan cikakkiyar dabarar tana tabbatar da cewa ƙirarmu ta daidaita daidai da buƙatun abokin ciniki kuma yana ba da garantin kyakkyawan aiki a cikin yanayi na ainihi.

Samfurin Zane-zane

Taimaka wajen ƙididdigewa da ƙirƙira da'irorin maganadisu dangane da bukatun abokin ciniki.La'akari na farko na sarrafawa da tafiyar matakai, kuma bisa ga kwarewarmu da sakamakon lissafin, ba da shawarar ingantawa don ƙira mara kyau na abokin ciniki.A ƙarshe, cimma yarjejeniya tare da abokin ciniki kuma sanya hannu kan odar samfur.

Da fari dai, dangane da kwarewarmu da lissafin taimakon CAE, ana samun mafi kyawun samfurin.Mahimman bayanai na samfurin shine cewa ya kamata a rage yawan adadin maganadisu kuma siffar maganadisu ya zama mai sauƙi don na'ura.A kan wannan, injiniyoyi suna la'akari da tsarin ƙirar don sauƙaƙe sarrafawa da haɗawa.Tsara ra'ayoyinmu da sadarwa tare da abokan ciniki, kuma a ƙarshe sanya hannu kan samfuran samfuri.

Haɓaka matakai da samfurori

Haɓaka dalla-dalla matakai da haɓaka wuraren sa ido masu inganci.Zane-zanen samfurin na'urar maganadisu ya fara samarwa.

Kayan aiki na ƙira: 1. Tabbatar da siffa, matsayi, da jurewar juzu'i na sassan;2. Ana amfani dashi don auna kayan aiki don tabbatar da inganci.

Wannan misali ne na ƙirar gwajin mu na musamman.Bayan sanya hannu kan odar samfurin, dangane da halaye na sarrafawa da haɗuwa, muna buƙatar haɓaka cikakkun matakai da haɓaka ingantaccen kulawa a cikin mahimman matakai.A lokaci guda, muna samar da kayan aiki na kayan aiki.A wannan matakin, ana amfani da kayan aikin don tabbatar da juriyar juzu'i da juzu'i na sassa da samfuran duka, da kuma gwajin sigina don tabbatar da cewa samfuranmu za a iya bincika cikin sauri da inganci a cikin batches na gaba.

Sarrafa samar da girma

Bayan karɓar umarni mai yawa, shirya ma'aikata don yin aiki, shirya wuraren aiki da tsari cikin hankali, kuma idan ya cancanta, ƙirƙira kayan aiki na musamman don sarrafawa don rage ƙarfin aiki da tabbatar da daidaito a cikin samar da tsari.

Magnet na lalata kayan aiki

Maɗaukakin maganadisu na dindindin, maganadisu na motsa jiki, da wasu majalissar maganadisu suna buƙatar maganadisu don yin maganadisu kafin haɗuwa.Kwarewar maganadisu da hannu ba shi da inganci, kuma abu mafi mahimmanci shi ne cewa yana da zafi a cire maganadisu da yatsu na dogon lokaci.Don haka, mun ƙirƙira da kera wannan ƙananan kayan aiki don kawar da zafin ma'aikaci gaba ɗaya da haɓaka aiki.

Kayan aikin gluing ta atomatik

Yawancin mahaɗaɗɗen maganadisu da abubuwan haɗin gwiwa suna buƙatar amfani da manne don haɗa ƙaƙƙarfan maganadisu da sauran abubuwan haɗin gwiwa tare.Ba kamar manne da hannu ba, ba za a iya sarrafa adadin manne ba.Mun tsara da kuma kera kayan aikin gluing na atomatik musamman don samfuranmu, wanda ya fi dacewa da inganci idan aka kwatanta da kayan aikin da aka sayar a kasuwa.

walda Laser atomatik

Yawancin samfuran odar mu suna buƙatar walƙiya na laser na kayan aiki don dalilai na rufewa (wasu abubuwan magnetic suna buƙatar rufewa gaba ɗaya).A zahiri waldi, da workpieces da tolerances kuma akwai thermal nakasawa a lokacin waldi;Ba abu ne mai amfani ba don walda manyan umarni da hannu.Mun ƙirƙira kuma mun kera na'urori na musamman da yawa don baiwa masu farawa damar farawa da sauri.

Muna da kwarewa mai yawa a cikin sarrafawar samarwa, kuma muna buƙatar cimma iko mai ƙididdigewa a cikin duk matakai don tabbatar da daidaito a cikin kowane samfurin samfurori.

KYAUTA & BADA

Tambaya&A

Q: Akwai zane?

A: Mun inganta da kuma tsara jerin nau'o'in haɗin kai, kuma abokan ciniki na iya yin gyare-gyare bisa ga wannan.Kuma muna maraba da abokan cinikinmu don kowane ayyuka na musamman.

Q: Menene samfurin, farashi, da lokacin jagora?

A: A farkon aikin haɗin gwiwar maganadisu, ana buƙatar gwajin samfurin koyaushe, don haka muna karɓar umarni samfurin.Koyaya, don tantance abokan ciniki tare da niyyar batch, za mu cajin mafi girman ƙimar samfurin.Za mu cajin kuɗin samfurin daga 3000 zuwa 8000 yuan don karfin juzu'i daga 0.1 Nm zuwa 80 Nm, kuma lokacin bayarwa gabaɗaya shine kwanaki 35 zuwa 40.

Q: Yaya game da girma MOQ da farashin?

A: Dangane da ƙayyadaddun wahalar sarrafawa, yanke hukunce-hukuncen da aka yi niyya da ambato.

Q: Kuna da wani kaya?

A: Magnetic couplings yawanci musamman musamman.Alal misali, idan abokan ciniki suna buƙatar ramukan shaft daban-daban, muna buƙatar sake yin aiki da sassan, don haka ba mu adana samfuran da aka gama ba.Duk samarwa da aka keɓance, babu kaya.

Q: Shin Magnetic couplings zai rasa aikin maganadisu?

A: Magnetic couplings suna amfani da maganadisu na dindindin don watsa juzu'i ba tare da gibi ba.Lokacin da maganadisu na dindindin ya lalace ko ya rasa zumuɗi, haɗaɗɗiyar maganadisu ba ta da tasiri.Babban hanyoyin demagnetization na maganadiso na dindindin sun haɗa da babban zafin jiki, rawar jiki, filin maganadisu baya, da sauransu. Saboda haka, haɗin gwiwar maganadisu dole ne yayi aiki a cikin yanayin daidaitacce na rotors na ciki da na waje.Lokacin da nauyin ya yi girma sosai, na'urar rotor ta waje ta sake yin lodin filin maganadisu na baya akan rotor na ciki, wanda ke da sauƙin ragewa, yana haifar da raguwa ko rashin nasara.

Q: Menene ya kamata in kula da lokacin shigar da haɗin gwiwar maganadisu?

A: Magnetic coupling shi ne watsawar da ba ta sadarwa ba, tare da wani tazara tsakanin na'urar rotor na waje da keɓewa, da kuma tsakanin keɓaɓɓen hannun riga da rotor na ciki, yana rage wahalar shigarwa.Duk da haka, kaurin bango na keɓe hannun yana da sirara sosai, kuma idan ya yi karo da wasu abubuwan da aka gyara ko ɓangarorin da ke da ƙarfi yayin aiki, zai lalata hannun keɓewa kuma ya kasa yin aiki azaman hatimi.Saboda haka, wajibi ne a tabbatar da wani mataki na coaxial bisa ga daban-daban yarda.

Q: Yadda za a zabi samfurin?

A: Da fari dai, ƙayyade jujjuyawar ƙananan haɗin gwiwa dangane da ƙimar ƙarfin da aka ƙididdige ƙimar motar.Ƙididdigar ƙididdiga mai ƙaƙƙarfan ƙididdiga ita ce haɗuwa da karfin juyi (Nm) = 10000 * ikon motsa jiki (kW) / saurin mota (RPM);Abu na biyu, wajibi ne a fahimci yanayin zafin aiki, matsa lamba na aiki, da matsakaitan anti-lalata.Haɗin gwiwar mu na maganadisu yana buƙatar gudun ƙasa da 3000RPM da matsin aiki na ƙasa da 2MPa.

Q: Ta yaya madaidaicin maganadisu na dindindin ke aiki?

A: Magnet Couplings kuma ana samun su ta nau'ikan tsari daban-daban.Abubuwan haɗin haɗin gwiwar mu na dindindin suna amfani da ƙa'idar ƙaƙƙarfan maganadisu da ke jawo juna don watsar da ba ta sadarwa ba.Ya ƙunshi rotors ciki da waje, waɗanda aka haɗe da manyan maɗaukaki masu ƙarfi.Motar tana fitar da na'urar na'ura ta waje don juyawa yayin da ake canja wurin makamashin motsi zuwa na'urar motsi ta ciki ta hanyar da'irar maganadisu na ciki da na waje, yana haifar da na'ura mai juyi ta ciki don juyawa tare da aiki tare.Irin wannan nau'in haɗin gwiwar maganadisu yana samun daidaitaccen hatimi saboda rashin ƙaƙƙarfan haɗin kai tsakanin raƙuman watsawa na ciki da na waje kuma ana amfani da shi sosai a tsarin watsawa don gurɓataccen ruwa, mai guba, da gurɓataccen ruwa ko iskar gas.