Zaɓin kayan maganadisu daidai

Zaɓin zaɓin kayan magana mai dacewa don aikace-aikacenku na iya zama ƙalubale. Akwai nau'ikan kayan maganadisu da za a zaɓa daga cikinsu, kowannensu yana da halaye daban-daban. A matsayin ƙwararren mai siyar da maganadisu, tare da ƙwarewarmu mai yawa a cikin maganadisu, za mu iya taimaka muku yin zaɓin da ya dace.

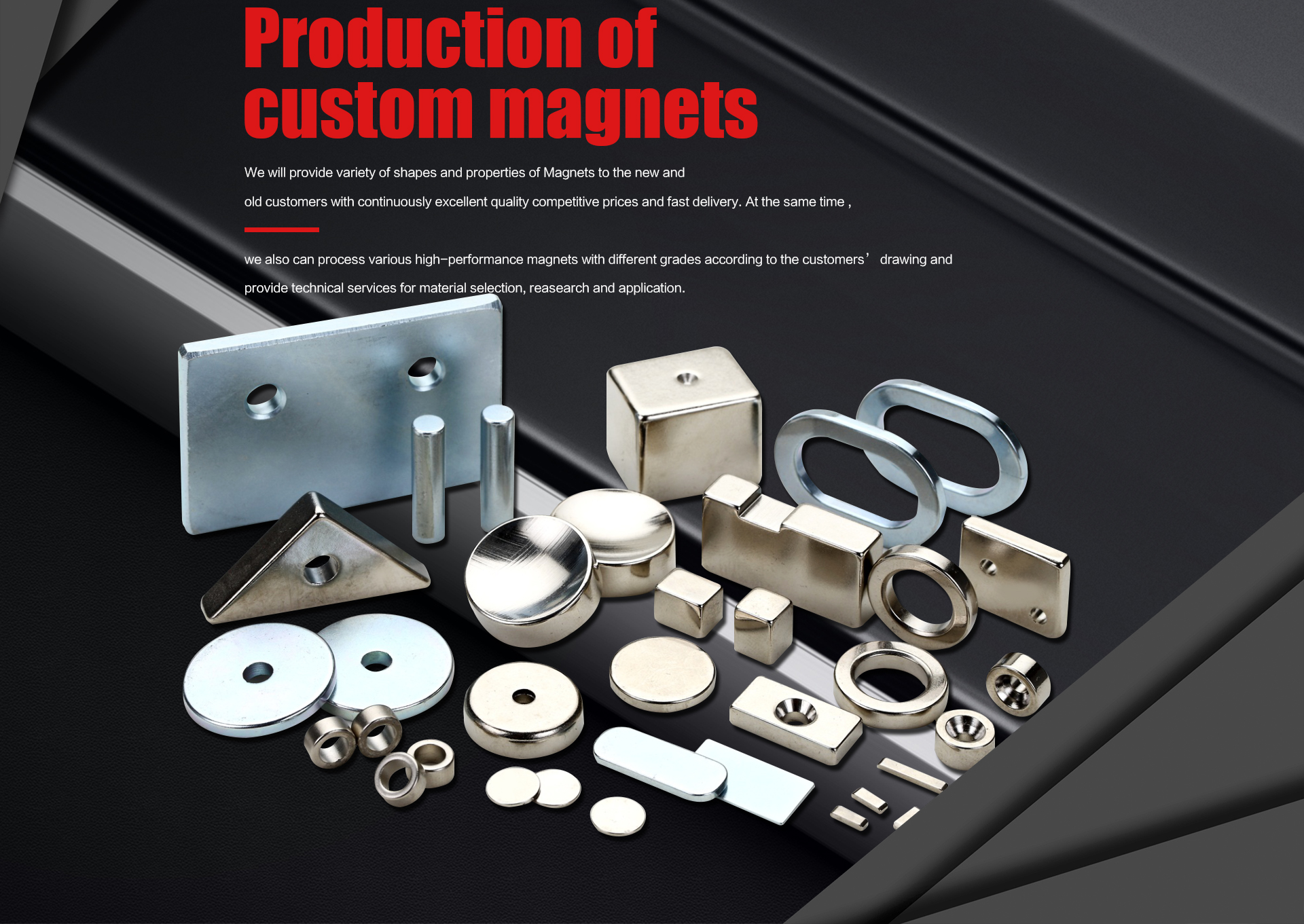

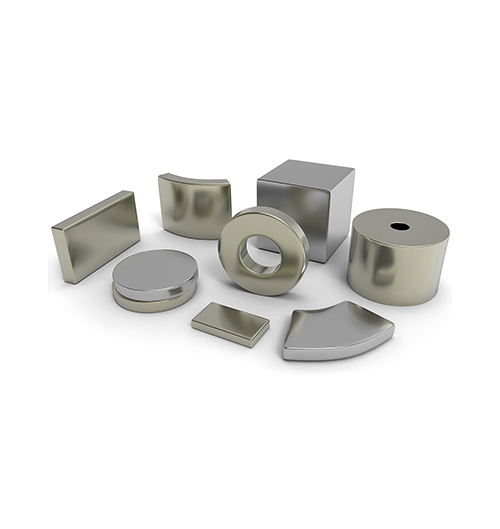

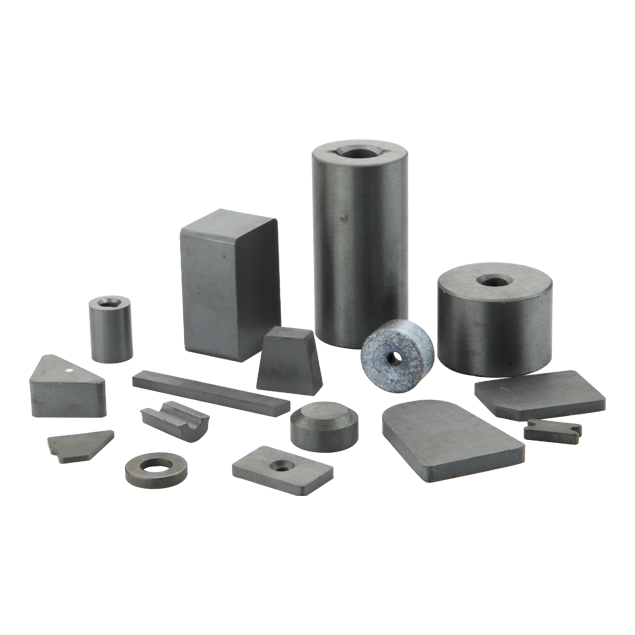

Akwai abubuwa da yawa da suka haɗa da maganadisu neodymium (NdFeB ko ƙasa mai wuya), alnico maganadiso (AlNiCo), samarium cobalt (SmCo) ko ferrite maganadisu ( yumbu). Bugu da kari, akwai sigogi daban-daban kamar electromagneets, manyan magarai da kuma ɗaure magnanne. Zaɓin kayan da ya dace shine mabuɗin aikin nasara.

Nawa nau'ikan maganadisu daban-daban suke akwai

Ana iya rarrabuwa mai sauƙi na waɗannan maganadiso bisa ga abubuwan da ke tattare da abubuwa daban-daban da tushen maganadisu. Magnets da ke zama magnetic bayan magnetization ana kiran su magneti na dindindin. Kishiyar wannan ita ce electromagnet. Electromagnet maganadisu ce ta wucin gadi wacce kawai ke aiki kamar maganadisu na dindindin lokacin kusa da filin maganadisu, amma yana rasa wannan tasirin da sauri idan an cire shi.

Yawancin maganadiso na dindindin ana kasu kashi hudu bisa ga kayansu: NdFeB, AlNiCo, SmCo da ferrite.

Neodymium iron boronNdFeB) - wanda aka fi sani da neodymium iron boron ko NEO maganadiso - su ne rare duniya maganadiso da alloying neodymium, baƙin ƙarfe da boron, kuma su ne mafi ƙarfi na dindindin maganadisu samuwa a yau. Tabbas, ana iya raba NdFeB zuwa sintered NdFeB, bonded NdFeB, compression injection NdFeB da sauransu. Koyaya, gabaɗaya, idan ba mu ƙididdige wane nau'in Nd-Fe-B ba, za mu koma zuwa Nd-Fe-B da aka haɗa.

Samarium CobaltSmCo) - wanda kuma aka sani da rare earth cobalt, rare earth cobalt, RECo da CoSm - ba su da karfi kamar neodymium maganadiso (NdFeB), amma suna bayar da uku manyan abũbuwan amfãni. Magnets da aka yi daga SmCo na iya aiki akan kewayon zafin jiki mai faɗi, suna da madaidaicin zafin jiki kuma sun fi juriya ga lalata. Saboda SmCo ya fi tsada kuma yana da waɗannan kaddarorin na musamman, ana amfani da SmCo a aikace-aikacen soja da na sararin samaniya.

Aluminum-Nickel-CobaltAlNiCo) - Duk manyan abubuwa uku na AlNiCo - aluminum, nickel da cobalt. Ko da yake suna da juriya da zafin jiki, ana rage su cikin sauƙi. A wasu aikace-aikace, sau da yawa ana maye gurbinsu da yumbu da maɗaukakin ƙasa da ba kasafai ba. Ana amfani da AlNiCo sau da yawa a rayuwar yau da kullun don aikace-aikacen tsayawa da koyarwa.

Ferrite- Ceramic ko ferrite na dindindin maganadiso yawanci ana yin su ne daga sintered iron oxide da barium ko strontium carbonate kuma ba su da tsada kuma suna da sauƙin samarwa ta hanyar latsawa ko latsawa. Wannan yana ɗaya daga cikin nau'ikan maganadisu da aka fi amfani da su. Suna da ƙarfi kuma ana iya lalata su cikin sauƙi.

Ana iya raba maganadisu na dindindin zuwa nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan iri daban-daban:

Sintering- shine canza kayan foda zuwa gaji mai yawa kuma tsari ne na gargajiya. Mutane suna amfani da wannan tsari na dogon lokaci don samar da yumbu, foda karfe, kayan haɓakawa, kayan zafi mai zafi, da dai sauransu. Gaba ɗaya, jiki mai yawa da aka samu ta hanyar sintiri bayan an ƙera foda shine kayan polycrystalline tare da microstructure. wanda ya ƙunshi lu'ulu'u, humor vitreous da pores. Tsarin sintiri kai tsaye yana rinjayar girman hatsi, girman pore da siffar da rarraba iyakokin hatsi a cikin ƙananan ƙwayoyin cuta, wanda hakan yana rinjayar kaddarorin kayan.

Bonding - Bonding ba wani siga ba ne na musamman a cikin ma'anar kalmar, kamar yadda haɗin kai shine haɗin kayan da aka haɗa tare ta hanyar mannewa. Ta wannan hanyar za a iya rage magudanar ruwa da ake samu yayin aikace-aikacen maganadisu, tare da inganta amincin maganadisu yayin aikace-aikacen.

Injection Molding - Injection gyare-gyare hanya ce ta samar da siffofi na samfuran masana'antu. Yawancin samfuran ana yin su ta hanyar yin amfani da gyare-gyaren allura na roba da gyare-gyaren allurar filastik. Hakanan za'a iya raba gyare-gyaren allura zuwa hanyar yin gyare-gyaren allura da hanyar gyare-gyaren mutuwa. Yin amfani da gyare-gyaren allura azaman hanyar samarwa na iya samar da ƙarin dama ga sifofin maganadisu. Saboda kaddarorin masu maganadisu da kansu, maɗaukakin maganadisu sau da yawa suna da rauni sosai kuma suna da wahalar samarwa don takamaiman siffofi. Hanyar gyare-gyaren allura sau da yawa yana yin ƙarin siffofi ta hanyar haɗa wasu kayan.

Magnet mai sassauƙa- Magnet mai sassauƙa shi ne maganadisu da za a iya lanƙwasa da gurɓatacce kuma abubuwan da ke cikin maganadisu suna nan. Yawanci ana yin su da abubuwa masu sassauƙa irin su roba, polyurethane, da sauransu, kuma ana haɗa su da foda na maganadisu don yin maganadisu. Ba kamar ƙaƙƙarfan maganadisu na gargajiya ba, maganadisu masu sassauƙa sun fi sassauƙa da mallewa, don haka ana iya yanke su da lankwasa su da sifofi daban-daban idan an buƙata. Hakanan suna da mafi kyawun abubuwan mannewa kuma ana iya amfani dasu don a

Solenoid: Kishiyar maganadisu na dindindin shine electromagnet, wanda kuma ana iya kiransa maganadisu na wucin gadi. Wannan nau'in maganadiso shine coil wanda ke samar da madauki ta hanyar nannade wayoyi a kusa da wani abu mai mahimmanci, wanda kuma aka sani da solenoid. Ta hanyar wucewar wutar lantarki ta hanyar solenoid, filin maganadisu da ake amfani da shi don yin maganadisu na electromagnet yana samuwa. Filin maganadisu mafi ƙarfi yana faruwa a cikin coil, kuma ƙarfin filin yana ƙaruwa tare da adadin coils da ƙarfin halin yanzu. Electromagnets sun fi sassauƙa kuma suna iya daidaita alkiblar filin maganadisu bisa ga alkiblar halin yanzu, kuma suna iya daidaita ƙarfin halin yanzu kamar yadda ake buƙata don cimma ƙarfin filin maganadisu da ake so.

Lokacin aikawa: Afrilu-21-2023